200W 300W MOPA Amanzi okupholisa umatshini wokucoca iLaser

Iimbonakalo

1. Isoftware elula, khetha iiparamitha ezigcinwe ngokuthe ngqo

2. Ugcino lwazo zonke iintlobo zeparameter yemizobo, iindidi ezintandathu zegraphic zingakhethwa: umgca othe ngqo/ujikelezo/ isangqa/uxande/uxande ukugcwaliswa/ukuzaliswa kwesangqa.

3. Kulula ukuyisebenzisa kunye nokusebenza

4. Iindlela ezahlukeneyo ze-12 zingatshintshwa kwaye zikhethwe ngokukhawuleza ukuququzelela ukuveliswa kunye nokulungiswa

5. Ulwimi lunokuzikhethela, isiNgesi / isiTshayina okanye ezinye iilwimi (ukuba ziyafuneka)

6. Umatshini wokucoca i-laser uhambelana ngakumbi ekuyilweni kunye nobukhulu obuncinci kunye nobunzima obulula.

7. Umzimba womatshini wokucoca i-laser wenziwe kumgangatho ophezulu wentsimbi yentsimbi kunye neendawo ezingundoqo zokuxhasa ziqiniswa ngakumbi.

Isicelo

1. Kwintsimi yokuveliswa kwamashishini, izixhobo zomatshini sele zisebenza ixesha elide, kwaye inani elikhulu leoli, inkunkuma yepeyinti, i-rust kunye ne-carbon deposits ziye zaqokelela phezu kwendawo kunye namacandelo.Itekhnoloji yokucoca iLaser iphucula kakhulu impembelelo yekhabhoni yokubeka kunye nomgangatho wenkqubo ye-welding.Iyakwazi ukucoca ngokufanelekileyo i-carbon deposition kumphezulu we-substrates ezahlukeneyo, ukunciphisa iziphene ze-welding, kunye nokuphucula i-weldability yezixhobo;kwangaxeshanye, inokonga iindleko zemveliso yeshishini, ukukhulisa ukusebenza kakuhle kwemveliso yeshishini.

2. Kwintsimi ye-microelectronics processing, i-polyimide yimpahla ye-dielectric yesakhiwo soxhumo lwangaphakathi lweefilimu zokupakisha ze-elektroniki.

3. Ishishini loomatshini abachanekileyo ngokufuthi kufuneka lisuse ii-esters nee-mineral oils ezisetyenziselwa ukuthambisa kunye ne-anti-corrosion kumalungu, ngokuqhelekileyo ngeendlela zekhemikhali, kwaye ukucocwa kweekhemikhali kaninzi kusenazo iintsalela.I-laser degreasing inokususa ngokupheleleyo i-esters kunye neoyile yamaminerali ngaphandle kokonakalisa umphezulu weendawo.

Iiparamitha

| Igama lepharamitha | Ixabiso leParameter |

| Uhlobo lweLaser | I-nanosecond pulse fiber yasekhaya |

| Awona mandla emveliso aphezulu(W) | 200/300 |

| Ubude obuphakathi (nm) | 1064±5 |

| Uluhlu lolawulo lwamandla (%) | 10-100 |

| Ukungazinzi kwamandla emveliso (%) | ≦5 |

| Ukungazinzi kwamandla emveliso (kHz) | 10-50/20-50 |

| Ubude bokubetha (ns) | 90-130/130-140 |

| Awona mandla okubetha kwentliziyo (mJ) | 10/12.5 |

| Ubude bosinga oluqhubayo (m) | 5 okanye 10 |

| Iklasi yokukhusela iLaser | 4 |

| Imo yokupholisa | ukupholisa amanzi |

Ulwakhiwo

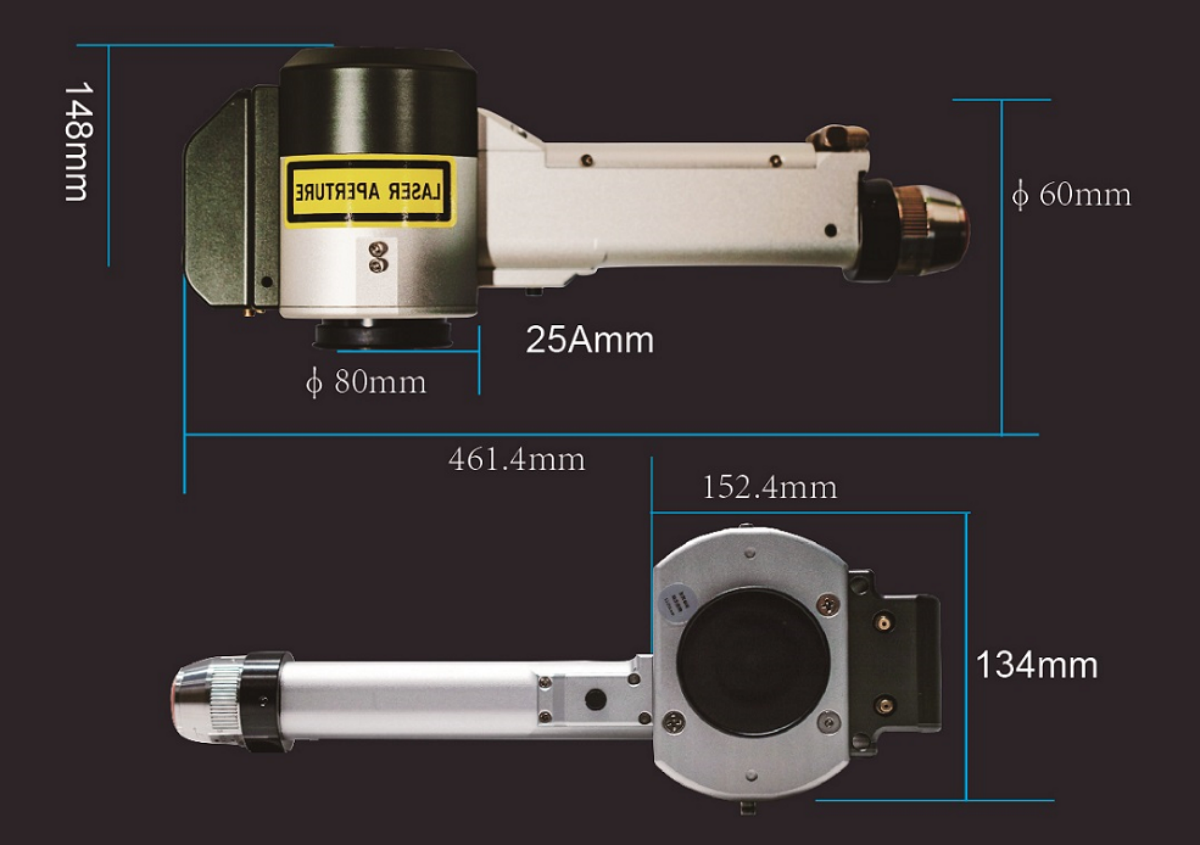

Ubungakanani bentloko bokucoca ngeLaser: